| ||||

| Home > All By Location regional map > Ambridge > I-79 Neville Island Back Channel Bridge | ||||

|

|

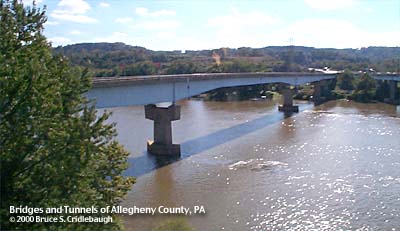

View south from Neville Island (downstream right)

OFFICIAL NAME: OTHER DESIGNATION: I-79 Neville Island Back Channel Bridge ambr573-20, amb573-20a, 573-19 LOCATION: Robinson Twp - Neville Twp USGS 7.5" Topo Quad - UTM Coordinates: Ambridge - Zone 17; 0573 4484 CARRIES: Downstream span: Raymond P. Shafer Memorial Highway [I-79]; Yellow Belt, six lanes divided Upstream span: Exit 18 Neville Island from northbound Interstate 79 to Grand Av, one lane northbound only BETWEEN: -- Neville Island Bridge over Ohio River main channel (Neville Twp) -- Neville Rd, Grand Av (Neville Twp) -- Middletown and Coraopolis Rd [PA51] (Robinson Twp) CROSSES: -- Ohio River back channel at Mile 8.7 -- CSX RR [PLE RR] TYPE OF CONSTRUCTION / DESIGN: steel deck girder LENGTH OF MAIN SPAN: Downstream span [I-79]: 301.0 ft Upstream span [Exit 18 ramp]: 300.0 ft TOTAL LENGTH (including longest elevated ramp): HEIGHT OF DECK: 45.0 ft Dashields Dam normal pool level 692 ft YEAR ERECTED / ENGINEER: 1971-76 (closed for repairs 1977) PennDOT ADDITIONAL INFO: (Interstate 79 Neville Island Bridge over Ohio River main channel) The back channel bridge gained worldwide notoriety in the winter of 1977. Only five months after a gala ribbon-cutting which opened the final link in the 180-mile Interstate 79, a 10-foot long crack in one of the bridge girders was noticed by a tow boat operator. The $50 million bridge was closed for three months while PennDOT made repairs. The defects were blamed on an electroslag welding process. Other bridges built during this time, including the 1976 Birmingham Bridge over the Monongahela River, were also checked and repaired. The Federal Highway Administration prohibited further use of electroslag welding on all bridge tension members. Over the past 20 years, conventional processes, such as submerged arc welding and shielded metal arc welding, were used instead. A new technique Narrow Gap Improved Electroslag Welding (NGI-ESW) has been developed. From the FHWA website: "Electroslag welding is a process used to join thick steel plates in a vertical position. A consumable guide bar is placed between the plates. This bar guides an electrode wire. The plates are joined together by melting the plate edges, the guide bar, and the electrode wire in a pool of molten metal shielded by a flux bath (slag). The flux is kept molten due to electrical resistance to the current passing through the slag." "With NGI-ESW, the magnitude of electric current applied is much greater than in conventional electroslag welding, and the gap between the plates, and hence the amount of molten material used, is relatively small. This results in a higher welding speed." More hairline cracks were found in the Neville Island girders in 1999. $1.8 million was budgeted for those repairs. Holes are bored at the ends of the cracks to relieve the strain and prevent the cracks from spreading further. Pittsburgh Press Roto article, June 5, 1977: view page - "The Award-Winning Bridge That Failed" by William Allan Jr. FIELD CHECKED: INFO SOURCES: USACE Ohio River Nav. Charts; Pittsburgh Post-Gazette; FWHA website; www.electroslag.com Submit info or inquiry - share some facts or ask a question. Introduction -- Nearby Structures Page created: 21-Nov-2000 Last modified: 21-Nov-2000 |

View Larger Map

| ||

| copyright: © Bruce S. Cridlebaugh 1999-2008 All Rights Reserved | ||||